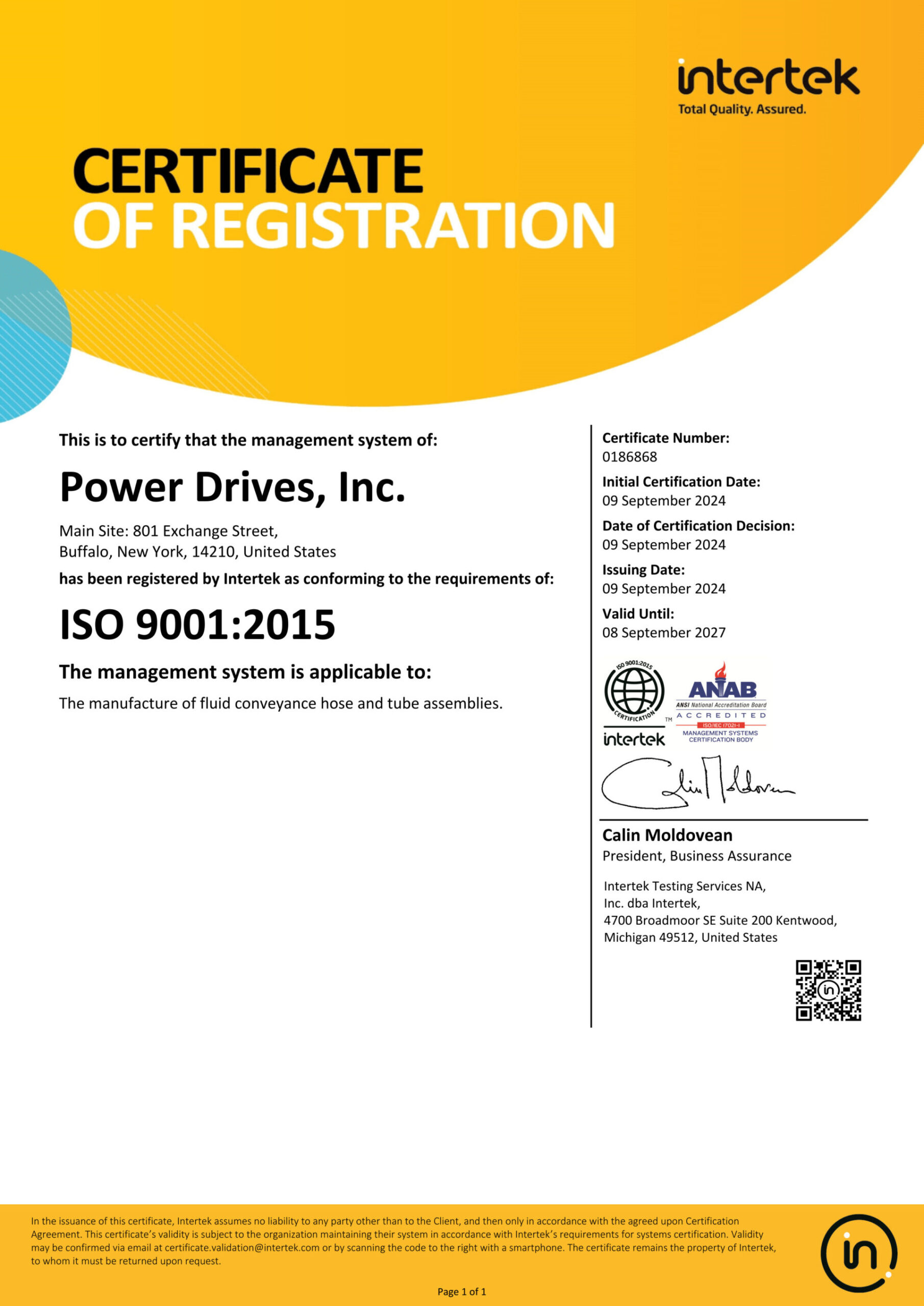

Power Drives, Inc. has been established for the better part of the last century. Our history, strong vendor relationships and longstanding commitment to quality have positioned us as a leader in the industry. Our management system is certified to ISO 9001:IATF 16949:2016 and our quality statement is simply: “Delivering Quality Products on Time…Every Time.”

PDI utilizes the following Quality Core Tools:

Advanced Product Quality Planning (APQP)

- Potential Failure Mode and Effects Analysis (FMEA)

- Measurement Systems Analysis (MSA)

- Production Part Approval Process (PPAP)

- Process Flow Diagrams

- Control Plans

- Process Studies

- Product Characteristics Evaluation

- Material Evaluations

- Dimensional Layout Capabilities

- Instrument Calibration

- Cleanliness Testing

PDI’s laboratory scope includes 3-D measurement capabilities. Measurement devices and instruments are calibrated to gauges that are traceable to NIST certification. Our cleanliness testing capabilities include:

- Product Cleanliness Testing and Evaluation per ISO 16232 (Gravimetric Testing)

-

- Particle Counting by particle count and maximum particle size and weight

- Cleaning to ISO Standards and Customer Standards

PDI also pressure tests pneumatically for mass flow and pressure decay, and hydrostatically for pressure decay.